Description

56 Cubic Meter LPG Tanker Semi-Trailer

Solving the industry’s long-standing pain points: insufficient capacity, inefficient loading/unloading, and high compliance risks—with ZW GROUP’s customized solutions.

ZW GROUP LPG Transportation Solutions

Our 56 cubic meter LPG tanker semi-trailer is engineered to break industry bottlenecks—combining lightweight design, rapid operations, and strict compliance.

Maximized Capacity

56m³ effective volume (loads ~28 tons of LPG) reduces transportation frequency, cutting logistics costs by 15-20%.

Rapid Loading/Unloading

DN80 pneumatic quick-connect valves cut operation time to 25-30 mins (vs. 60+ mins for traditional tankers).

Strict Compliance

Meets ADR (EU) and GB (China) standards—ideal for both transnational and domestic transportation.

Product Design: Efficiency by Engineering

Every detail is optimized for performance—from aerodynamics to lightweight structure, ensuring cost savings and reliability.

Streamlined Elliptical Tank

-

Optimized Dimensions

Length-to-diameter ratio of 4.5:1 for 56m³ precise effective volume—loads ~28 tons (based on 0.5kg/L LPG density).

-

Gradient Wall Thickness

8-12mm tank walls (gradient design by pressure needs) balances strength and lightweight—15% lighter than traditional tanks.

Aerodynamics & Energy Savings

-

Low Drag Coefficient

Drag coefficient of 0.65 (vs. ~0.8 for traditional tankers) reduces air resistance during transit.

-

Fuel Efficiency

12R22.5 low-rolling-resistance tires + aerodynamic design cut fuel consumption by 12% per trip.

Rapid Loading & Unloading System

-

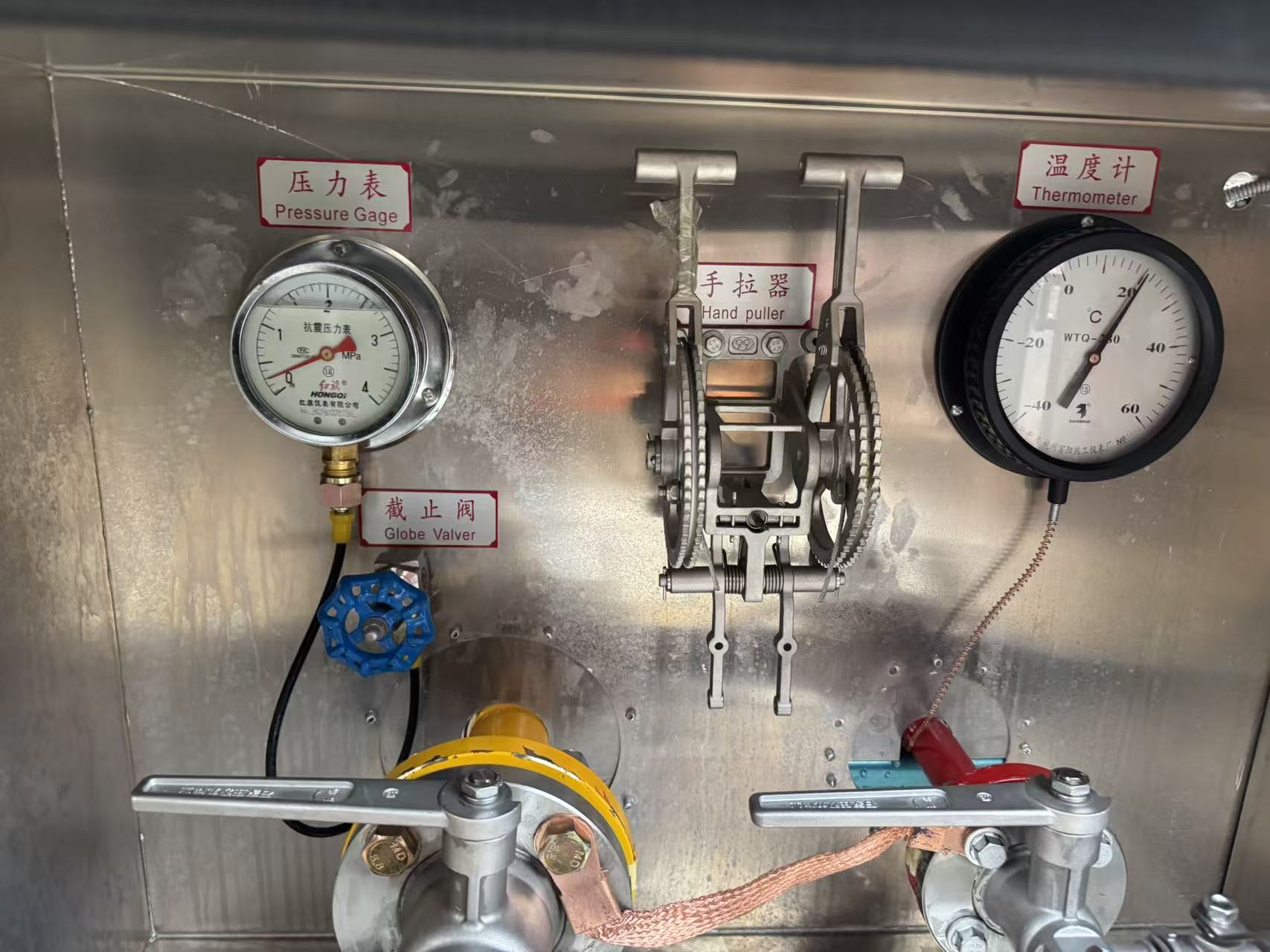

DN80 Pneumatic Valves

Large-diameter quick-connect valve group + intelligent flow control (1200L/min) slashes operation time to 25-30 mins.

-

Leak-Proof Sealing

Self-sealing gas-liquid phase interfaces with leakage rate < 0.1%—ensuring safety and raw material purity.

Scenario Adaptability

Engineered to perform in diverse environments—from mountainous roads to chemical parks, and emergency supply scenarios.

Mountainous Roads

- 3-axle air suspension chassis

- Reinforced braking system

- ≥320mm minimum ground clearance

Chemical Park Transfer

- ±0.02MPa gas phase control accuracy

- Leak-free transfer technology

- Meets fine chemical purity needs

Emergency Supply

- "Mobile gas storage station" function

- Supports 1,000 households for 7 days

- Ideal for winter heating seasons

Industry Applications

Trusted by urban gas providers and chemical manufacturers for reliable, efficient LPG transportation.

Urban Gas Security

Meets peak gas demand in densely populated areas. Large 56m³ capacity reduces transportation frequency, lowering carbon emissions per unit of LPG by 25%.

Chemical Raw Material Transport

Provides "door-to-door" transport for propylene/butane producers. Anti-wave plate structure minimizes liquid sloshing, ensuring continuous production line operation.

Customized Solutions for Industry Pain Points

ZW GROUP doesn’t just sell equipment—we solve problems with tailored engineering.

Pain Point: Insufficient Capacity & High Costs

Small tankers require "frequent trips with low efficiency," driving up labor and fuel costs.

ZW GROUP Solution

56m³ large-volume design reduces transportation frequency by 30%, cutting comprehensive logistics costs by 15-20%.

Pain Point: Poor Scenario Flexibility

Different sites (small gas stations vs. large factories) have varying loading/unloading needs.

ZW GROUP Solution

Modular valve groups and control panels allow adjustable pressure (0.2-1.6MPa) and flow rate—doubling adaptability.

Industry Trends: Lightweight & Sustainable

ZW GROUP stays ahead of the curve with innovations that align with global sustainability goals.

Lightweight Technology Revolution

As the industry shifts toward sustainability, ZW GROUP is pioneering the use of composite materials (e.g., carbon fiber) in tanker design. These materials further reduce tank weight by 20-25% while maintaining structural integrity—boosting unit transportation capacity and cutting carbon footprints.

We respect your privacy. Your information will only be used to process your quote request.

Contact ZW GROUP

Have questions about our 56 cubic meter LPG tanker semi-trailer? Our team is ready to assist you with technical support, customization, and after-sales service.

.png)