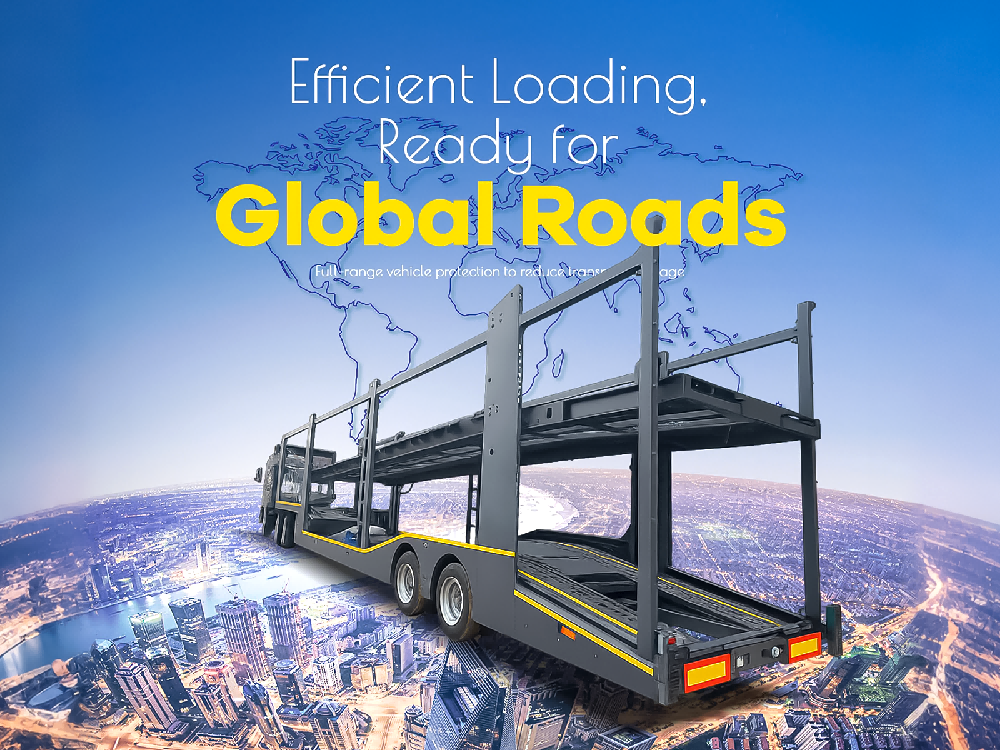

How to Select the Most Suitable Car Transporter Semi-Trailer for Your Needs

Choosing the right car carrier semi-trailer is essential for your business success. It helps you optimize single-trip profits and significantly lowers your long-term operating costs. Our diverse product line offers options ranging from budget-friendly models to premium, fully protected versions. We design these trailers to meet various transport environments and protection needs across global markets.

Selecting the Right Body Structure

You must first decide on the body structure based on your specific cargo. There are three primary types of car carrier designs available.

Skeletal Car Carrier Trailers

The skeletal model uses a pillar-style side structure without any side panels. This design offers an extremely light curb weight. Consequently, it reduces fuel consumption and lowers initial purchase costs. It is the ideal choice for companies seeking maximum logistics efficiency.

Semi-Enclosed Car Carrier Trailers

The semi-enclosed trailer features stamped corrugated side panels but lacks a roof. It offers a balanced performance by keeping the weight relatively low. Furthermore, the side panels provide a barrier against external impacts and scratches.

Fully Enclosed Car Carrier Trailers

For high-value vehicles, the fully enclosed trailer provides the best protection. It includes side panels, a front plate, a rear door, and a roof. While it is heavier, it guards against rain, dust, and flying stones. This model ensures your cargo arrives in pristine condition every time.

Optimizing Chassis Configurations

Your choice of chassis affects both loading capacity and available space. We offer two main rear axle structures to fit your specific business needs.

Dual-Axle Single-Tire (4 Tires)

This configuration features a very low center of gravity. Additionally, it provides significant space behind the gooseneck area. Therefore, it is perfect for hauling SUVs or microvans.

Dual-Axle Double-Tire (8 Tires)

This setup uses heavy-duty 13-ton axles from top brands like ZW. It offers much stronger load-bearing capacity and better driving stability. Depending on the trailer length, you can transport between 5 and 24 vehicles.

Improving Efficiency with Smart Accessories

We include ergonomic accessories to speed up the loading and unloading process. These features make the daily operations easier for your drivers.

First, our telescopic system allows the upper rear section to extend outward. This design maximizes the use of the total trailer length. Second, we install pull-out ladders and manual ramps at the rear. These tools allow workers to access the platform easily for vehicle maintenance or securing.

Partner with Us for High Performance

Our innovative designs, such as the dual-axle single-tire concave bridge, help you increase profits. We use components from famous international brands to ensure every trip is reliable. Whether you need a skeletal or enclosed model, we meet global compliance standards. Contact us today for professional procurement advice and high-performance car carrier solutions.

.png)